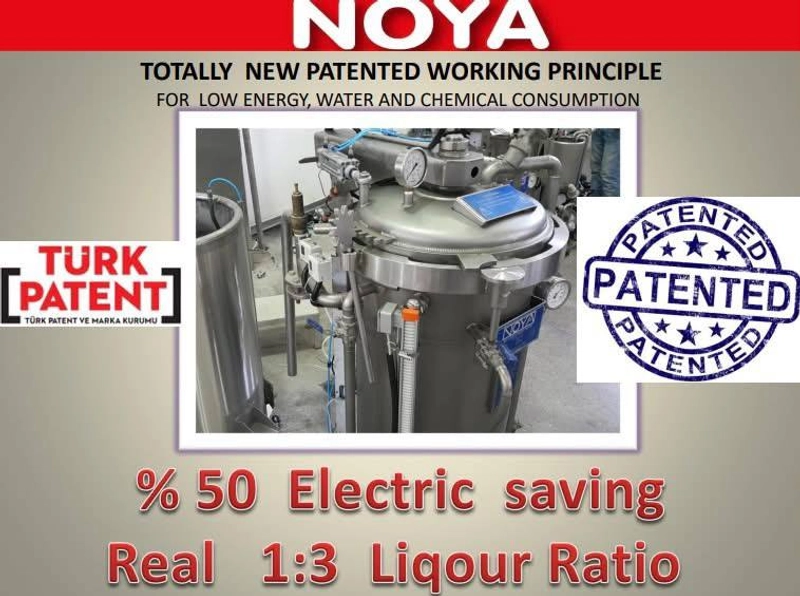

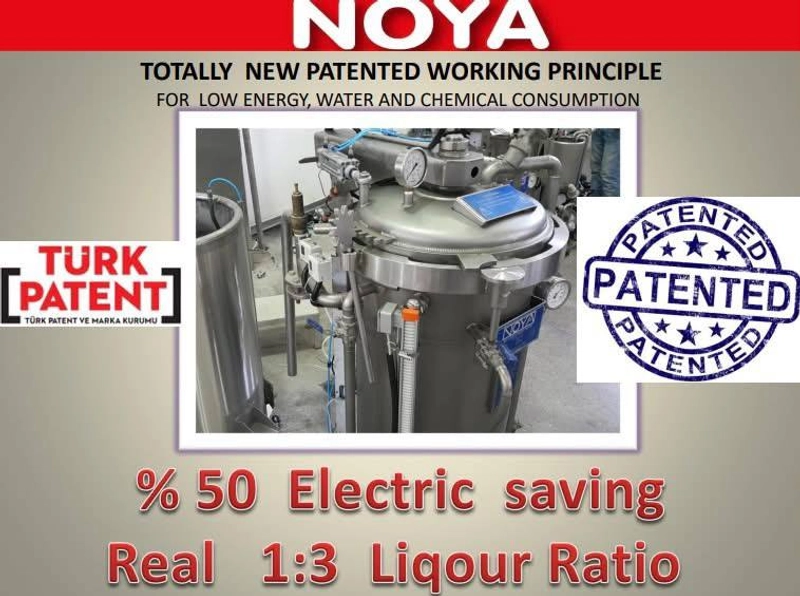

İplik Boyama Makinesi (PATENTLİ SİSTEM)

Ürün fiyatı

Talep üzerine fiyat

Ödeme ve gönderim bilgileri

İplik Boyama Makinesi (PATENTLİ SİSTEM)

Noya Mekatronik

Ürün detayları

HT İplik Boyama Makinesi, likör akışı, likör sirkülasyonu ve maksimum verimlilik ile ilgili en son teknik ve teknolojik gelişmelere dayanarak tasarlanmıştır. Makine, bobin paketleri, manşonlar, kirişler, gevşek malzeme, üstler vb. Gibi farklı uygun taşıyıcılar kullanılarak birçok farklı malzeme türünün işlenmesi için kullanılabilir.

Teknik Özellik

TECHNICAL ADVANTAGES Perfect dyeing results without having unlevelled dyeing effect for max. 2 kg bobbins in weight. Inside/outside and outside/inside two way flow without changing the direction of the snail pump motor. Short and fast heating times by efficient heat exchanger Dyeing capacity of min 50% and max. 100% with air pad system Perfect dyeing possibility on every pressure with differential pressure transmitter Repeatability by automation system Short dyeing times with the help of 100% reserve tank Liquor ratio in between 1:5 - 1:8 Single or double material carrier Heat exchanger in the circulation pipe line Rapid lid opening, closing, locking system Heavy duty stainless steel centrifugal pump with mechanical seal. DRYING PROCESS CONSISTS OF 3 SEQUENCES; HYDROEXTRACTION: replaces centrifugal operation and is done directly after loading of wet yarn carrier coming from dyeing machine. DRYING: Drying process starts automatically alter hydroextraction. The air is blown by the blower through heat exchanger for heating, heated at preset temperature according to yarn type and colour shade, flows at high speed through the yarn 1/0 direction, thereby transferring heat to the yarn and saturating with evaporated water. Duration of drying phase is preset on the base of air temperature at inlet and outlet of yarn packages 3 - YARN CONDITIONING: After the drying phase, air is circulated O/l direction in order to equalize residual humidity in yarn packages and reduce the temperature of the yarn. ADVANTAGES: No need of centrifuge hydro extractor. Loading and unloading is the waste time and also yarn packages may be damaged during loading /unloading. Process time is 50% to 70% shorter due to closed loop. Labour is dramatically reduced in the whole drying process.

Nakliye limanı

Türkiye

Izmir Port

Tedarikçi hakkında

Tedarikçi sayfasını ziyaret edinTedarikçi ile iletişime geç

Tedarikçiden daha fazla ürün

Benzer ürün

H901 model A 0.75-...

H901 serisi yüksek performanslı akım vektör invertörü...

JIANGSU ROBIN KAN...

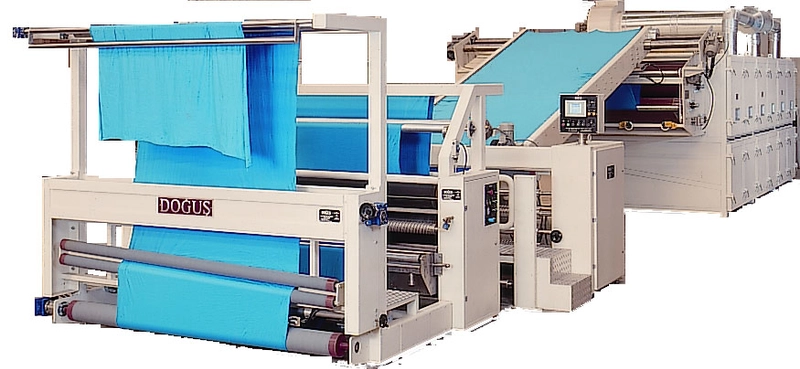

Balon Squuzer Maki...

Hidro ekstraktör aşağıdaki gibi dört ana işleve sahip...

Noya Mekatronik

İplik Boyama Makin...

HT İplik Boyama Makinesi, likör akışı, likör sirkülas...

Noya Mekatronik

Borulu Isı Ayarlam...

Borulu Isı Ayar Makinesi - 3 hazne uzunluğuna ve Etki...

Noya Mekatronik

ELEKTRONİK JAKAR D...

DEJ22-5376, Ahmedabad, Gujarat merkezli tanınmış bir ...

Dynamic Looms

ZbMaxj 88 Yüksek H...

Pamuk ipliği, kot ipek, ipek, viskon vb. İçin uygundu...

Jiangxi Zhongbo I...

Zbmax98j tipi yüks...

Pamuk ipliği, kot ipek, ipek, viskon vb. İçin uygundu...

Jiangxi Zhongbo I...

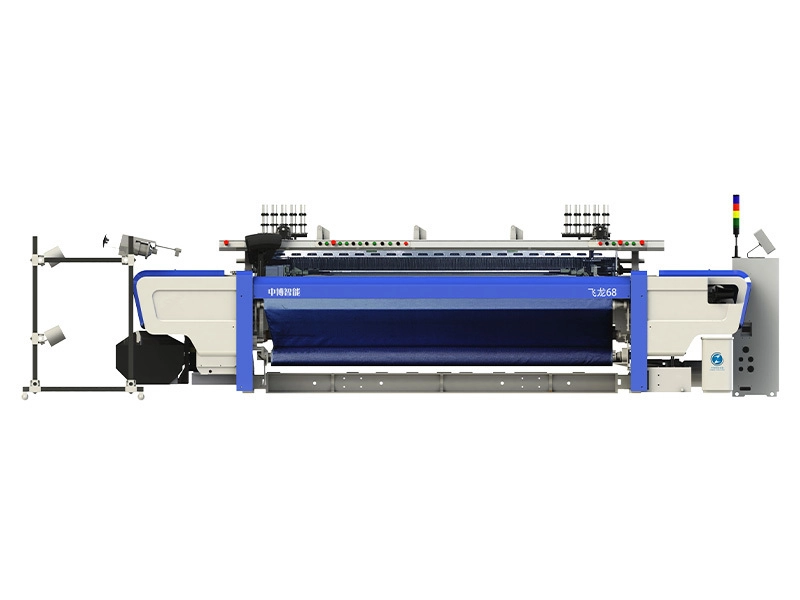

Feilong Model 68 Y...

Pamuk, kenevir, harmanlanmış, kimyasal elyaf, cam ely...

Jiangxi Zhongbo I...

ZbMax 88 Yüksek Hı...

Pamuk, kenevir, harmanlanmış, kimyasal elyaf, cam ely...

Jiangxi Zhongbo I...

Tekstil Elektronik...

Daha yüksek çıktı, yerleştirme cihazları tarafından s...

Jiangxi Zhongbo I...